New industry research lists top causes of collisions in underground mines

In June 2023, a group of experts from Ontario’s underground mining industry gathered to address an important concern: collisions involving mobile equipment, pedestrians, light vehicles, and fixed facilities that put workers at risk.

“This initiative is part of Workplace Safety North’s commitment to a risk-based approach to enhance health and safety in the workplace,” says Robert Marin, Health and Safety Specialist at Workplace Safety North (WSN). Marin and his colleague Sam Barbuto, WSN Health and Safety Specialist, facilitated the research workshop with industry.

The collaborative process

Subject matter experts, representing both labour and management, worked together to identify and analyze root causes and effective controls for decreasing this risk.

“The approach taken during the workshop was characterized by openness, transparency, and collaboration,” notes Marin. “It ensured that all perspectives and viewpoints were heard and respected. The final list of identified risks was shared with all participants before the workshop concluded, and the results were reviewed and validated to ensure accuracy.”

Importantly, the process focused on finding solutions that industry experts could support, rather than seeking a consensus, although results showed a significant degree of convergence. The emphasis was on addressing the most critical risks through a data-driven approach.

Identifying the key risk

The outcome of this collaborative effort was the confirmation and development of a comprehensive risk statement as an initial step in the root cause analysis.

The risk statement addressed ‘Collisions or contact between mobile equipment, pedestrians, light vehicles, and/or fixed facilities causing harm to workers.’ The “Fishbone” diagram approach was used to define the root causes of the problem accurately.

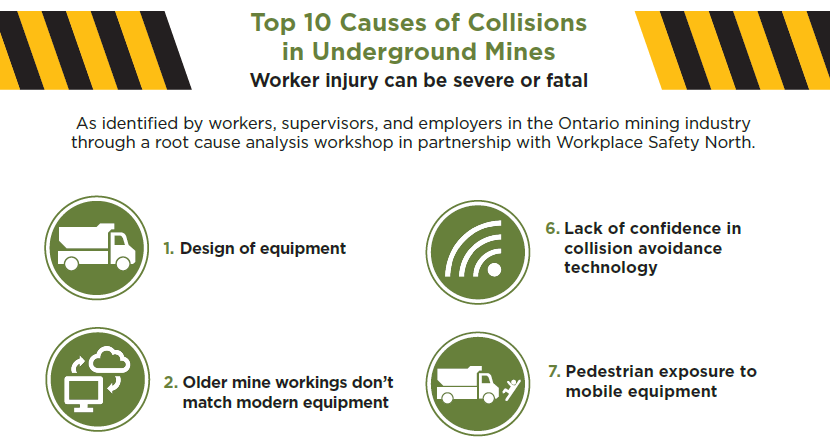

Top 10 causes of collisions in underground mines

The workshop participants identified the top 10 root causes of collisions in underground mines, acknowledging that worker injuries could range from severe to fatal.

These root causes were determined through input from workers, supervisors, and employers from the Ontario mining industry, facilitated by Workplace Safety North.

- Equipment design: Inadequate equipment design was a significant contributing factor.

- Older mine workings: Older mines didn’t always work well with modern equipment.

- Non-compliance to procedures and standards: Failure to follow safety protocols was a recurring issue.

- Ineffective traffic management program: Sometimes, the way vehicles moved around in the mine was not safe

- Inadequate communication systems: Poor communication made it hard for people to stay safe.

- Lack of confidence in collision avoidance technology: Some workers didn’t trust the technology meant to keep them safe.

- Pedestrian exposure to mobile equipment: People walking near moving equipment were in danger.

- Distracted driving: Distractions while operating vehicles were a common problem.

- Fit for work: Ensuring that workers were fit for their tasks was sometimes overlooked.

- Ineffective assessment of training competencies: Inadequate evaluation of worker training.

What needs to happen now?

To make mines safer, the workshop recommended taking these steps right away:

- Better equipment design: Use proximity detection cameras and work with equipment manufacturers to improve safety.

- Legislate clearance requirements: Ensure equipment has the necessary clearances from walls and safety bays.

- Review site-specific equipment commissioning checklists: Make sure equipment is designed to consider blind spots, line-of-sight, mine workings, infrastructure dimensions, speed, braking, and cab ergonomics, and illumination.

- Strong collision avoidance systems: Use reliable collision avoidance systems and follow legal requirements.

- Provincial guidelines: Create provincial guidelines for choosing and using equipment, with help from the Ontario Mining Association (OMA) and equipment manufacturers.

Being ready for the future

“The results of the workshop will be shared with committees in charge of mining safety: the Mining Legislative Review Committee (MLRC) and the Provincial Mining Tripartite Committee (MTC),” says Marin. “They will use these findings to make future health and safety-related initiatives and supports for the mining sector.”

The workshop’s findings will also help create better safety practices, make sure everyone knows the rules, and train supervisors properly.

A safer future for Ontario mines

The collaborative efforts of experts from the Ontario underground mining industry, representing both labour and management, have led to a proactive approach to addressing the critical issue of collisions and contact incidents in underground mines.

By finding the root causes and taking targeted steps, the industry is making big strides toward keeping workers safe. These measures, along with the ongoing support of Workplace Safety North, will contribute to a safer and more secure future for the mining sector in Ontario.

Related

Mining poster: Top 10 Causes of Collisions in Underground Mines